6.7 Powerstroke

Did you know that Ford shared its first truck with the world on July 27, 1917? Since 1917 there have been plenty of trucks added to Ford’s collection along with innovative engines. Today we are going to chat a little more about Ford’s first diesel engine in the Powerstroke category.

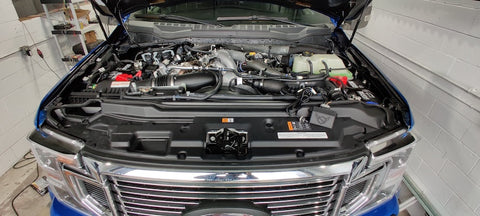

If you were not aware the 6.7 Powerstroke V-8 was Ford’s first diesel engine for its F-series pickup trucks. It was designed, engineered and manufactured exclusively by Ford for the Super Duty. It was nicknamed Scorpion during pre-production because of the unique position of the turbocharger mounting right on top of the block.

6.7 Powerstroke History

Manufactured by the American foundry company, Tupy, the engines are transported to Chihuahua, New Mexico for assembling. The engine features six-bolt main bearing caps and instant start “Glow Plugs” which can quickly start even in the cold weather. The engine uses compacted graphite iron block for reduced weight and fractured cap Mahle connecting rods.

In order to lower piston temperatures, the engine features piston cooling jets which spray oil on the bottom of the piston, which then travels through a cavity in the piston, cooling the top before exiting. This results in lowered combustion temperatures and improved life of the engine. The 6.7L Powerstroke is also B20 biodiesel compatible and has an improved 18% mileage compared to the older 6.4L engines.

Within the first three years of production itself, Ford managed to sell 500,000 6.7L powerstroke’s, meaning that Ford has successfully managed to impress the truck buyers despite facing their initial hesitation. Since their introduction, the engine has been subject to a lot of changes but none of them have degraded the engine’s performance or reliability.

Moreover, the improvements have resulted in a higher peak torque and power. In 2010, Ford even offered a free dealer-installed upgrade in order for 390 hp models to achieve the 400 hp power rating.

Fast Forward to 2020

Ford introduced the 3rd generation 6.7L powerstroke in 2020 models, with significant changes in the design. The most noticeable one is the introduction of steel pistons with a shorter height instead of the previous aluminium ones. Though it is slightly heavier than the previous ones, the smaller profile offers increased resilience and lower friction. Additional revisions for the newest model include changes in the designs of the variable geometry turbocharger, cylinder head, connecting rod bearing and main bearing.

Some engine block enhancements have also been introduced along with split stream piston cooling jets, new two-piece lower intake manifold, new injectors and a revised injection system. The 6R140 TorqShift transmission has also been replaced by a ten-speed 10R140 automatic transmission.

Meeting Federally Mandated Emissions Regulations

The 6.7L powerstroke Diesel has a network of emission control devices to meet Federally mandated emissions regulations. Some of them are diesel oxidation catalyst (DOC), diesel particulate filter (DPF), exhaust gas recirculation (EGR) system, and selective catalytic reduction (SCR) process. Exhaust gas recirculation (EGR) is a technique employed to reduce NOx emissions in combustion engines in which a metered portion of exhaust gases are recirculated through the intake where they are mixed with the incoming air charge. While the concept may seem counterintuitive, NOx emissions are reduced from lower combustion temperatures and from reduced oxygen concentration in the combustion chamber.

The DOC is basically a diesel equivalent of catalytic converter. As exhaust gases pass through DOC, residual hydrocarbons and carbon monoxide gases are converted to less harmful carbon dioxide and water vapor through oxidation reaction. The DPF captures particulate matter or soot from the exhaust also preventing the black buildup on the tailpipes.

Removal of DPF or manual cleaning is never required because the filter is cleaned by a process of known as “regeneration”, when it is full. In regeneration, the accumulated particles are burned off in the DPF. The SCR uses diesel exhaust fluid (DEF) to reduce NOx emissions. You want to make sure you monitor the DEF level or else the system will recognize it and will limit the speed and eventually the engine will enter “idle-only” mode.

What Are Your Thoughts on the 6.7 Powerstroke?

Now that you know more about the history of the 6.7 and where it stands today - what do you think about this engine? We would love to hear your thoughts below if you currently drive a 6.7 or have owned one in the past.

Ready for your next read? Check out our 5 Tips for Diesel Truck Maintenance to make sure you always have your diesel truck running its best.

Have you been looking to get an extra boost in performance in your Ford Truck? Make sure to check out how you can right here.

Have you checked out the 2020 Ford yet?